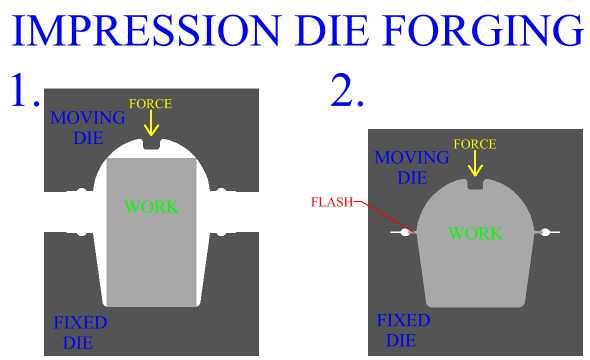

Impression die forging manufacture involves compression of a work piece by the use of impression die, (a mold), that contain cavities that act to restrict the flow of metal within the die during the deformation of the work. The metal will fill the space within the die cavity as it is plastically compressed into the mold. Closing of the mold completes the deformation, hence impression die forging is also referred to as closed die forging. The forged metal part will now have the geometric dimensions of the mold, provided a complete filling of the die cavity occurred during the process. The operation of forcing metal to flow into and fill the impressions in the die will also alter the grain structure of the metal. The creation of favorable grain structure through controlled material deformation should always be a consideration in the design of an impression die forging process.

One characteristic of impression die forging manufacture is the formation of flash or fin around the forged part. During the design of the metal forging operation, the volume of the starting work piece is made slightly higher than that of the closed die cavity. As the die close, and the work metal flows into and fills the contours of the impression, some excess material will flow out of the die and into the area between the two die. This will form a thin plane of metal all around the work at the parting line, (where the two die meet when they close), of the forged product. Flash is trimmed from the forging in a latter process.

Back To Forging

Classification of Forging

One characteristic of impression die forging manufacture is the formation of flash or fin around the forged part. During the design of the metal forging operation, the volume of the starting work piece is made slightly higher than that of the closed die cavity. As the die close, and the work metal flows into and fills the contours of the impression, some excess material will flow out of the die and into the area between the two die. This will form a thin plane of metal all around the work at the parting line, (where the two die meet when they close), of the forged product. Flash is trimmed from the forging in a latter process.

|

Classification of Forging

No comments:

Post a Comment